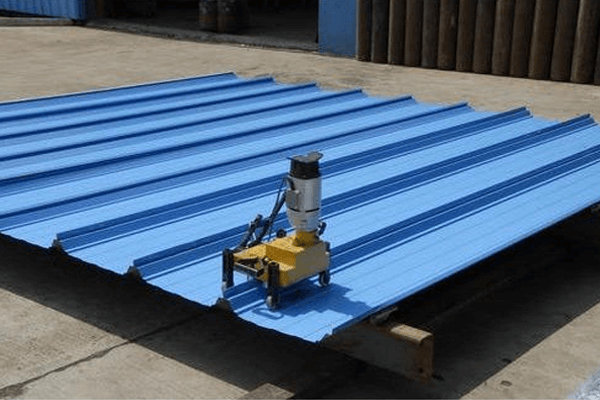

Standing Seam Profile – 1

Standing seam roofing is the most reliable roofing material. The risk of leakage is excluded due to concealed fixing, reliable seaming, and absence of through holes. Standing seam roofing blends into architectural character of cities thus being applied for new building construction as well as for remodeling and renovation.

Standing Seam Sheets

Standing Seam Sheets

Standing Seam Sheets

| Product | Effective width | Crest Dept | Crest Distance |

|---|---|---|---|

| Standing seam | 820mm | 50mm | 410 mm c/c With 2ribs at the centre for stiffening |

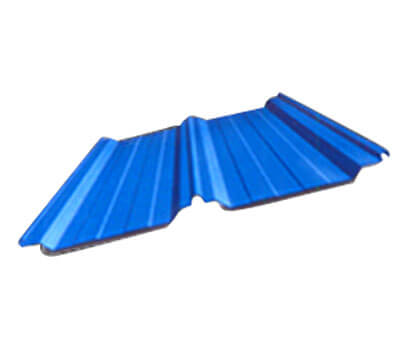

Standing Seam Sheets Profile – 2

| Product | Effective width | Crest Dept | Crest Distance |

|---|---|---|---|

| Standing seam | 485mm | 63mm | 410 mm c/c With 1rib |

Advantage

- On site rollforming thus providing single length sheet from Ridge to eve avoiding make weather.

- Tha channce of leakage is eliminated if roofing is properly seaned Easy and quick to install.

- Absense of throu8gh holes Prevents perforation corrosion both at joints and on surface thus ensuring for very low ultimate durability.

- Suitable for very low sloped Roofs.

- Standing seam profile roofs are used for low slope by means of single long sheets with no joints.

- This provides water tightness avoiding water leakage by usage of sealants and interlocking of the double lock type clips in the seams.

- It simplifies the roofing installation and faster installation.

- Preferred mostly architects and MNCs for their aesthetic beauty and very less maintenance.

- Standing seam profile is site fabricated using the color coated coils by means of roll forming machine and the sheets laid from the ridge to the gutter.

- No screws are used and hence long lasting.

- Offers excellent design flexibility.

- Mechanically seamed on the side laps.

- Long length full length sheets eliminate end laps.

- Can be produced and installed in lengths of up to 100m.

- Onsite production of the roof of eliminates damage to the sheets.

- Fire rated and light weighted.

- Standing seam roof can be laid in single skin or using insulations.

- Condensation free, durable and corrosion resistant.

- FM approved (USA).

- Very much preferred by EPC consultants and PMC companies.

- Very much energy efficient and contributes to LEED and Pearl rating certification.

- DBIT approved (Germany).

Technical Specification

| MATERIAL | PREPAINTED GALVANISED STEEL(PPGI) | PREPAINTED GALVANISED STEEL(PPGL) | NON-COLOUR GALVALUME STEEL(BG) |

|---|---|---|---|

| Base metal | cold rolled steel | cold rolled steel | cold rolled steel |

| Yield strength | 240MPA | 340MPA | 240Mpa |

| Metalic coating Specification. | Z120 g/m(gsm) | AZM 150 g/m(gsm) | AZM 150 g/m(gsm) |

| paint type on top coat | Regular Modified polyster(rmp)silicon modified polyster(SMP)poly viny di-flouride(PVDF2) | Regular Modified polyster(rmp)silicon modified polyster(SMP)poly viny di-flouride(PVDF2) | Non Colour |

| Product finish | Matt finish,Glossy finish | Matt finish,Glossy finish | natural |

| Masking | using polythene guard films | using polythene guard films | using polythene guard films |

| top coat thickness(dft) | 18-20 microns minimum | 18-20 microns minimum | – |

| Back coat | Epoxy/pu/polyester | Epoxy/pu/polyester | – |

| Back coat thickness(dft) | 5-7 microns minimum | 5-7 microns minimum | – |

| total coated thickness | 0.5 and above | 0.5 and above | 0.5 and above |

| Top Coat color | Refer our color card | Refer our color card | – |

| Back coat color | Grey as per mail standard. | Grey as per mail standard. | – |

| Back coat color | Grey as per mail standard. | Grey as per mail standard. | – |

| Confirmed standrad | ASTM A653/A653M,ASTM A755/A755M,IS 277/IS 513,IS 14246,JIS.3312,As 1397 | ASTM A792/A792/ASATM A755/A755M,JIS.3312,As 1397 | ASTM A792/A792/,JIS.3312,As 1397 |