Sandwich PIR/Fire Retardant Roof/Wall Panel

Sandwich PIR panels’ roof panels are combining low thermal conductivity ratio and good fire performance, this energy efficient PIR core panel both saves on heating costs and increases fire safety. Thanks to low weight this panel also offers savings on supporting structures as well as on freight and assembly costs. Ideal way to insulate any home or industrial premises and give higher thermal resistance is to have it insulated through particular roof insulation material. It can give you multiple benefits including applying it over the roof as well as under roof insulation. The process of applying insulation material is comparatively easy as most of the housing roof as well as industrial ceilings have some access for caring insulation work.

This PIR panel combines low thermal conductivity ratio and good fire resistance together with available thicknesses up to 200mm. Wall panels with PIR rigid foam core and steel shells in different structures and surfaces. It is an ideal solution for cold storages as well as for facades with ultimate requirements for energy efficiency and fire safety. Wall Sandwich Panels Division PIR by we are designed to fulfill several functions. The most important are: resistance to atmospheric factors, thermo insulation, aesthetics, durability, functionality and universality .The continuous core is an additional advantage, which improves aesthetic of the building.

| Cladding Steel | ||

|---|---|---|

| GENERAL SPECIFICATION FOR PIR- SANDWICH PANEL | ||

| SL.No | CHARECTERISTICS | SPECIFICATION |

| 1 | PRODUCT NAME | PPGI/PPGL-STEEL SHEETS COILS |

| 2 | REFERENCE STANDARDS | ASTM,A 7555(JIS 63312,IS14236,ECCA) |

| 3 | STRIP THICKNESS(TCT)-mm | 0.5 TOP/0.50 BOTTOM(OPTION AVAILABLE) |

| 4 | SUBSTRATE MATERIAL | Galume(AJ-Zn Alloy)Coating as per ASTM A792/A 792M withsteel base as per ASTM Std. |

| 5 | SUBSTRATE COATING MASS Gms/m2,SUBSTRATE COATING MASS CLASS | 120,AZM 150 as per ASTM Std. |

| 6 | GRADE DESIGNATION | Gr80 / CS Type A,B as per ASTM Std. |

| 7 | YIELD STRENGTH -Mpa min. | 240/550 for Gr80. |

| 8 | YIELD STRENGTH -Mpa min. | 240/550 for Gr80. |

| 9 | PAINT TYPE | RMP/SMP/PVDF(SMP&PVDF ON MOQ) |

| 10 | PAINT COATING THICKNESS(DFT) | RMP COATED-Top coat 18 to 22microns(+5 microns primer),Back coat 5 to 8 microns(Including Primer).& SMP COATED |

| SL.No | FOAM CHARACTERISTICS | UNIT | SPECIFICATION | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 11 | TOTAL FOAM DENSITY | Kg/m3 | 48+2 | |||||||

| 12 | CORE FOAM DENSITY | Kg/m3 | 44+2 | |||||||

| 13 | COMPRESSIVE STRESS AT10% DEFORMATION | kpa | >100 | |||||||

| 14 | YOUNG COMPRESSION MODULES | kpa | >2500 | |||||||

| 15 | FOAM TENSILE STRENGTH(ADHESION) | kpa | >100 | |||||||

| 16 | YOUNG TENSILE MODULE | kpa | >2500 | |||||||

| 17 | SHEAR STRENGTH | kpa/td> | >90 | |||||||

| 18 | THERMAL-CONDUCTIVITY-A@50C MEAN TEMP & B.@10C MEAN TEMP-MAX | kpa | A.0.03 &b.0.023 | |||||||

| 19 | HORIZANTAL BURNING TEST | mm | <25 | |||||||

| 20 | HOT DIMENSIONAL STABILITY AT 85+2C/100+2C FOR 24HRS-MAX | % | LENGH+2 | |||||||

| % | WIDTH+2 | |||||||||

| % | THICKNESS+2 | |||||||||

| 21 | COLD DIMENSIONAL STABILITY AT -25+2C FOR 24HRS-MAX | % | LENGH+2 | |||||||

| % | WIDTH+2 | |||||||||

| % | THICKNESS+2 | |||||||||

| 22 | WATER VAPOR TRANSMISION-Max | ng/pasm | 8.5 | |||||||

| 23 | PANEL WIDTH ROOF | mm | 1060MM | |||||||

| 24 | PANEL WITH WALL | mm | 1000 | |||||||

| 25 | REFERENCE PROFILE DRAWING | |||||||||

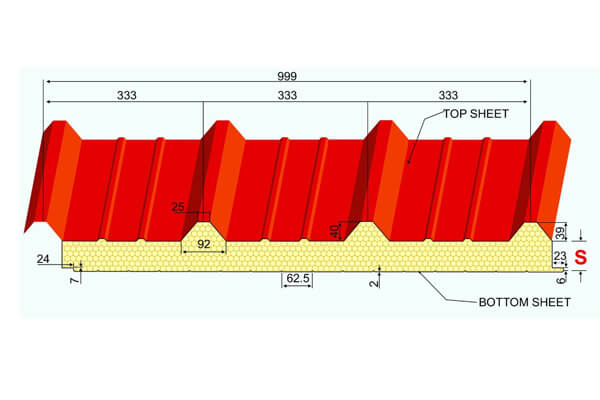

| 26 | ROOF PANEL PROFILE | |||||||||

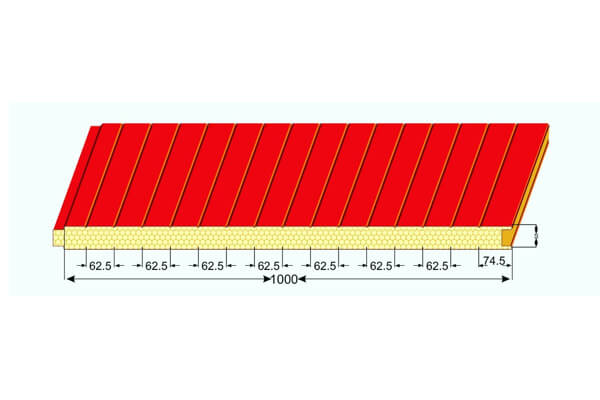

| 27 | WALL PANEL PROFILE | |||||||||

| 28 | HIDDEN WALL PANEL PROFILE | |||||||||