Pre Engineered Building

The Pre-engineered building system is one of the fast growing segments globally. It has all the attributes of what the modern life-style demands, i.e., speed, quality and value. there are many applications for pre-engineered buildings. it can be automobile garage to aircraft hangar, bakery to dairy farm, auditorium to hospital, and factory to community hall.

Advantages

| Reduction in project cost | Cost savings primarily result from time savings on the Project. This also results in earlier realization of revenue to owner on a commercial project |

| Saving in construction time | About 30-50% time saving in total project schedule due to fast delivery and quick site erection. |

| Low Maintenance | High quality paint systems are available for steel and cladding to be provided along with maintenance free service life |

| Large clear spans | Buildings can be supplied in clear spans up to 90 meter, particularly suitable for aircraft hangers, sports facilities, etc. |

| Flexibility in expansion | Buildings can be designed for future expansion in length, width and height. |

| Energy efficiency | Buildings are supplied with roof and wall insulation to reduce energy costs and improve comfort level inside the building |

| Superior quality | Complete manufacturing is done in our plant as per ISO 9001-2008 quality assurance standards |

Peb vs Conventional

| PEB Buildings | Conventional Building |

|---|---|

| Higher resistance to seismic forces due to low weight flexible frames | Special aesthetic design required |

| Reduced time because of international design standards & codes using standard sections and connections | Increased design time due to start from scratch and availability of less design aids |

| Higher resistance to seismic forces due to low weight flexible frames | Rigid heavy weight structures not suitable for seismic zones |

| 30% less PEB steel structures weight through efficient use of steel | High weight due to excessive safety factor and the usage of heavier steel sections |

| Factory controlled quality | Every project to be fabricated at site |

| Low initial cost of peb steel buildings(cost per square meter about 30% less than the conventional) and faster delivery | Special design and features developed for each project at higher costs |

| Simple Foundation, easy to construct and light weight PEB structures | Extensive heavy foundation |

| Average delivery time 6-8 weeks | Average delivery time 22-28 weeks |

Design codes

We design & manufacture in accordance with the following codes

Primary Steel Framing

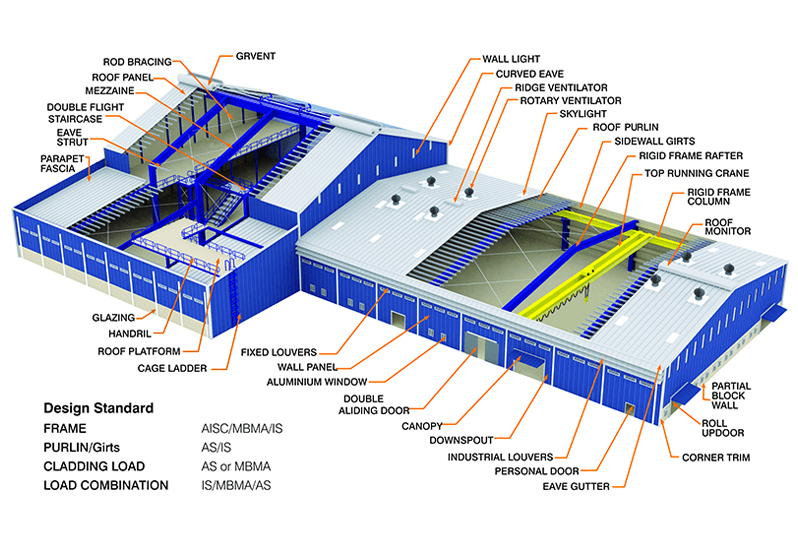

Cladding Steel Building Solutions pre-engineered buildings manufacturers Bangalore are custom-designed to meet your exact requirements. Each is designed by professional, experienced engineers and manufactured to exact tolerances under rigid quality controlled plant conditons. The steel plates are painted with a minimum of 25 Microns DFT of red oxideprimer. Each steel structural framing system is designed by experienced engineers and manufactured to precision tolerances under rigid quality controlled plant conditions. Some of common primary steel structural framing systems include

Structural Sub Systems

Cladding uses standard components and designs to manufacture a wide range of structural subsystems according to customers’ requirements. These structural subsystems fulfill the requirements of two types viz. Aesthetic and Functional. Cladding produces a large number of structural subsystems according to exact specifications as the strength of the pre-engineered building system depends largely on various incorporated structural subsystems. Subsystems are available for following structures.

- Endwall Roof Extension

- Sidewall Roof Extension

- Transverse Partition

- Longitudinal Partition

The examples of some structural subsystems offered by Cladding are

- Canopy

- Curved Eave with projection (without valley gutter)

Vertical fascia with back up panel and valley gutter

- Center Curved fascia

- Standard Roof Monitor

The examples of some structural subsystems offered by Cladding are

Vertical fascia with back up panel and valley gutter

Secondary Framing

Secondary members are load carrying members suitable to ensure the stability of the building against forces in any direction They include purlins and girts, eave strut, cable bracing and open steel web joists.

Secondary members have two other functions

- Act as struts that help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads

- Provide lateral bracing to the compression flanges of the main frame members thereby increasing frame capacity.