Flordec Sheets

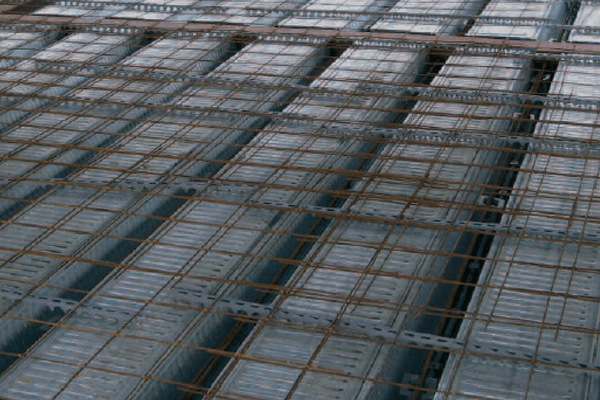

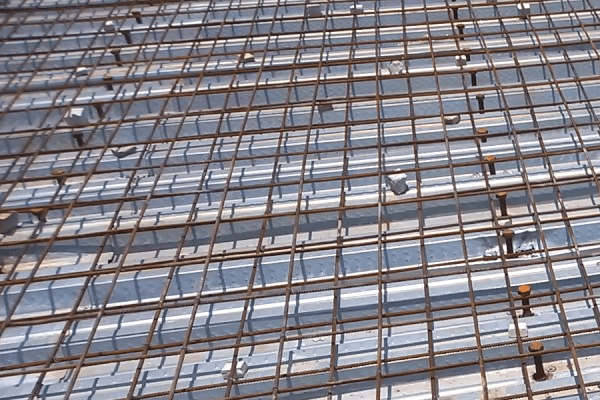

The floor is constituted by a profiled sheet onto which a layer of concrete is poured. The sheet is bonded to the concrete by means of mouldings on the sheet which stop the concrete from slipping horizontally and detaching vertically. When the concrete is poured and until it has reached an appropriate level of hardening.

(stage 1), the weights of the concrete, personnel working and equipment used in borne by the sheet alone. Once the concrete has hardened .

(stage 2) the sheet and the concrete form a unified bond with all the Characteristics of traditional reinforced concrete, where the sheet, after having performed the function of framework, acts as a metal reinforcement. Appropriate crop ends must be provided to absorb the negative moments.

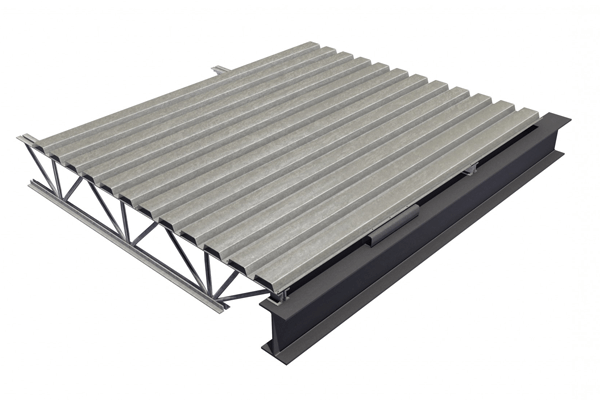

Decking Profile 75 / 305mm

- Reduced Concrete usage : Tensile steel for composite slab construction that cuts down on slab thickness and dead weight of buildings. Providing a more sustainable solution and reducing costs.

- No separate formwork required for slab casting.

- Reduces construction time.

- Technical department at Alfa offers comprahassive advisory of service on design of composite flooring should quiries arise when are not cover by this literature please contact us.

Base Metal

- High tensile structural grade steel

- Coating Mass 120, 180 & 275 GSM

- Coating Standard IS : 277

- Yield Strength 240 MPA / 350 MPA / 550 MPA

- Premier Coating Minimum 10 Microns

- Colour coating Premier 10 Microns Bottom 25 Micron

Available Finish

- Cold Rolled (CR)

- Pre coated galvanized under side giving durable and attractive appearance and minimum future maintenance. Thickness 0.8mm/1mm/1.2m

| Panel Thickness | Design Thickness | Profile Weight | Area of Steel | Height of neutral axis | Moment pof Lnertia | Moment of carying capacity | |

|---|---|---|---|---|---|---|---|

| Sagging | Hogging | ||||||

| mm | mm | kg.m2 | cm2 | mm | cm4 | KN.m/m | KN.m/m |

| 0.8 | 0.77 | 7.66 | 9.76 | 37.80 | 100.90 | 4.004 | 3.983 |

| 1.0 | 0.97 | 9.57 | 12.19 | 38.12 | 126.10 | 4.993 | 4.962 |

| 1.2 | 1.17 | 11.97 | 15.25 | 38.28 | 157.70 | 6.230 | 6.179 |

| fy= 25 Kn/cm2 E= 2.00E+08 KN/M2 |

|||||||

| Panel Thickness | Profile Weight | Sectional Area | Concrete slab depth above profile | |||

|---|---|---|---|---|---|---|

| mm | kg/m2 | cm2 | 100mm | 150mm | 200mm | 250mm |

| 0.80 | 7.66 | 9.76 | 2.90 | 2.50 | 2.30 | 2.000 |

| 1.00 | 9.57 | 12.19 | 3.30 | 2.80 | 2.50 | 2.300 |

| 1.20 | 11.97 | 15.25 | 3.70 | 3.20 | 2.80 | 2.600 |

- Light weight. Doesn’t require any support, which considerably reduces the use of concrete & slab thickness.

- Acts as composite member and as permanent shuttering.

- No major reinforcement required.

- Deck can be used as a working platform during construction.

- Speedy construction enables faster completion of a project.

- Decking reduces the construction time, hence the total cost.

Deck Sheet For Car Park

EXCLUSIVE FOR CAR PARK

Deck Sheet 75 can be manufactured with pre-finished steel coating to the underside. This is suitable for situations where a visibly exposed Deck soffit is required, such as in multi-storey car parks. The Deck soffit can be left exposed or where further protection is required it can form the base coat for further protective systems.

| No | Typical Properties | Test Specification | Test Values |

|---|---|---|---|

| 1 | Nominal coating thickness | ECCA T1 | 25 microns |

| 2 | Gloss (600) | ECCA T2 | 25-45% |

| 3 | Pencil hardness | ECCA T4 | 2H |

| 4 | Flexibility Reverse Impact Minimum Bend |

ECCA T5 ECCA T7 |

16J 4T diameter, 2T radius |

| 5 | Adhesion Cross Hatch |

BS 3900/E2 | 100% |

| 6 | Corrosion resistance Salt Spray Humidity UV resistance (QUV-A) |

ECCA T8 BS 3900/F2 ECCA T10 |

Galvatite® 500 hrs Galvatite® 1000 hrs Very good |

| 7 | Abrasion resistance (Taber) *1 | ASTM D4060 | <40mg |

| 8 | Scratch resistance | BS 3900/E2 | 2500mg |

| 9 | Maximum continuous operating temperature | 120ºC | |

| 10 | Minimum forming temperature | 20ºC | |

| 11 | Surface spread of flame | BS 476 Part 7 | Class 1 |

Performance

The 25 micron polyester coating on its own will be satisfactory in a dry and unpolluted environment (such as would be expected on most car park soffits) and will only require regular inspection or assessment after a period often years.

Application

Composite floor decking offers the same benefits to car parks as to other steel framed buildings. Primarily these are speed of erection and reduced carriage requirements. Furthermore the reduced structure weight, height, and the provision of a working platform during construction can be very significant advantages.

Durability of metal decking in car parks

Galvanised is the standard protective coating for composite steel decking, giving a sufficient level of corrosion protection to the upper surface of the decking, provided adequate provision has been made to prevent the ingress of water (using reinforcement to control cracking, and waterproofing to the top surface of the concrete). The top deck of the car park should be waterproofed with a traditional bituminous membrane or liquid applied seamless coating. It is also good practice to treat other floors to prevent ingress of water from above. Adequate falls and drainage should be provided, to prevent the build up of water on the slabs.

The underside of the decking may additionally be pre-finished (with Colorcoat Exterior Flexible Polyester) or by using epoxy paint applied in site, in order to provide a contemporary appeal or additional protection. Cladding will provide advice on durability or future maintenance depending on the preferred post-finish.

Car park roof

There is a growing trend to use a lightweight roof over the top parking deck. This gives added protection to the top floor of the car park allowing users to park in all weathers.

The aesthetic appeal of a car park can be significantly enhanced by this method enabling the car park to blend in with the urban environment. The long-term benefits of reduced maintenance can far outweigh the initial cost of this approach and will be benefitted from protection against the external climate.